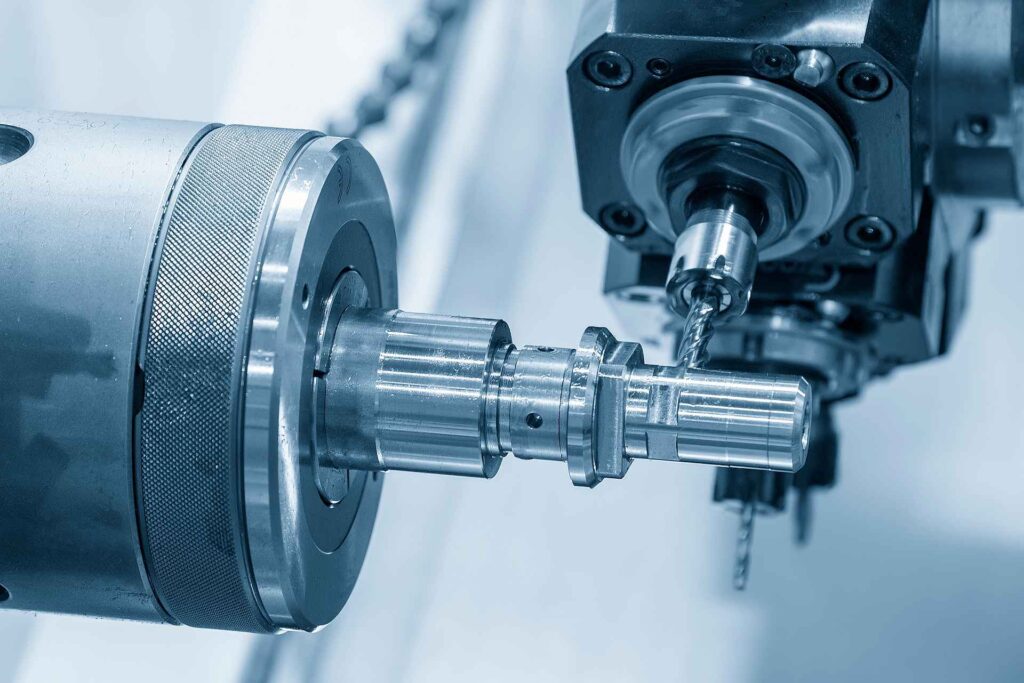

Global Precision Parts is known for our ability to create quality, high precision components, and one of the ways that we do that is through CNC Swiss machining. This type of multi axis machining has been around for well over a century, and has advanced alongside other manufacturing technologies to become the most precise CNC machining technique available today.

Swiss Multi Axis Machining–how does it work?

Swiss lathes were originally developed to create tiny components for watchmakers, and have since been adopted by other manufacturers around the world to create small, reliable components. This type of CNC machine works with round bar stock, which is fed into the tooling area using a guide bushing. The bushing secures the material in place and ensures that only the portion exposed to the tooling area is machined. The lathe can work on multiple axes, up to seven typically, guiding the tools with computer numerical control.

The result of this design is that these types of multi-axis machines can shape small or delicate features with high accuracy and without introducing unnecessary stress to the component. The combination of being able to operate on multiple axes simultaneously and keeping the bar stock stable during the process means that the stock won’t be exposed to vibration or other typical stresses introduced to the material during traditional machining.

The benefits of Swiss CNC Machining

The major benefit of Swiss machining is of course the tolerances that it can achieve extremely tight tolerances even on complex components. They can also accommodate a wide range of tooling in order to perform several different operations, sometimes simultaneously depending on the machine, such as tapping, drilling, turning, milling, and more. Even if the machine is not equipped to handle multiple operations at once, it’s still very efficient, performing multiple functions in one cycle without the need to readjust the workpiece.

The efficiency of Swiss machines also contributes to the production volumes they can handle, producing medium to large volumes of complex components at a much faster rate than other types of machining centers. Less downtime–and sometimes no downtime–is needed between different operations or steps in the production process, improving not just a machine shop’s productivity, but also the turnaround times that they can offer their customers. Swiss multi axis machining is one of the few manufacturing technologies that can offer faster production without sacrificing quality.

Looking for a supplier of multi axis machining capabilities?

Global Precision Parts is a leading provider of high-quality precision manufacturing services such as multi-spindle machining, CNC machining, Swiss screw machining, hydromat machining, and much more. Contact us to learn more about how we can serve you.